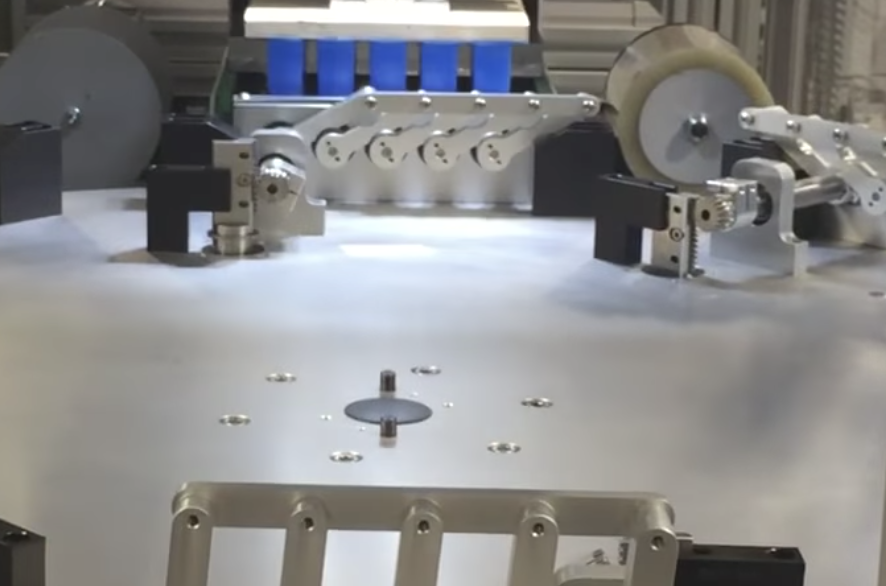

Dye-sublimation Process

All MTO garments are adorned using digital apparel dye sublimation printing equipment, which yields high-definition (HD) printing quality and deliver a color palette of 100,000’s of stunning colors, far exceeding other technologies.

With Dye Sublimation printing, solid dye molecules are printed on specially treated paper, and are converted into a gas when using heat and pressure. The dye, in a gas form, penetrates the fibers of the material, infusing or embedding the image into the fabric, assuring that it will not crack, peel or fade for the life of the garment.

Because of the chemistry involved in the sublimation process, it will only bond with polymers and polyester, so 100% polyester is the best choice. Dye Sublimation printing will not work for fabrics such as cotton, bamboo, wool etc.

Photolab Quality

Unlike ink-jet printing that uses individual dots, our dye-sublimation process allows us to print photo-lab-quality, realistic images every time.

Your Colors are Important

Dye sublimation decorated apparel is vibrant, bold, and colorful. There are no limitations and every garment we print will be as unique as the person who wears it.

The Advantages

No fading or flaking. Because the dye is sublimated in the fabric, it is permanent. Durability and appearance is why dye sublimation is superior over other garment printing processes.